Our Services

More Details

More Details

More Details

More Details

More Details

More Details

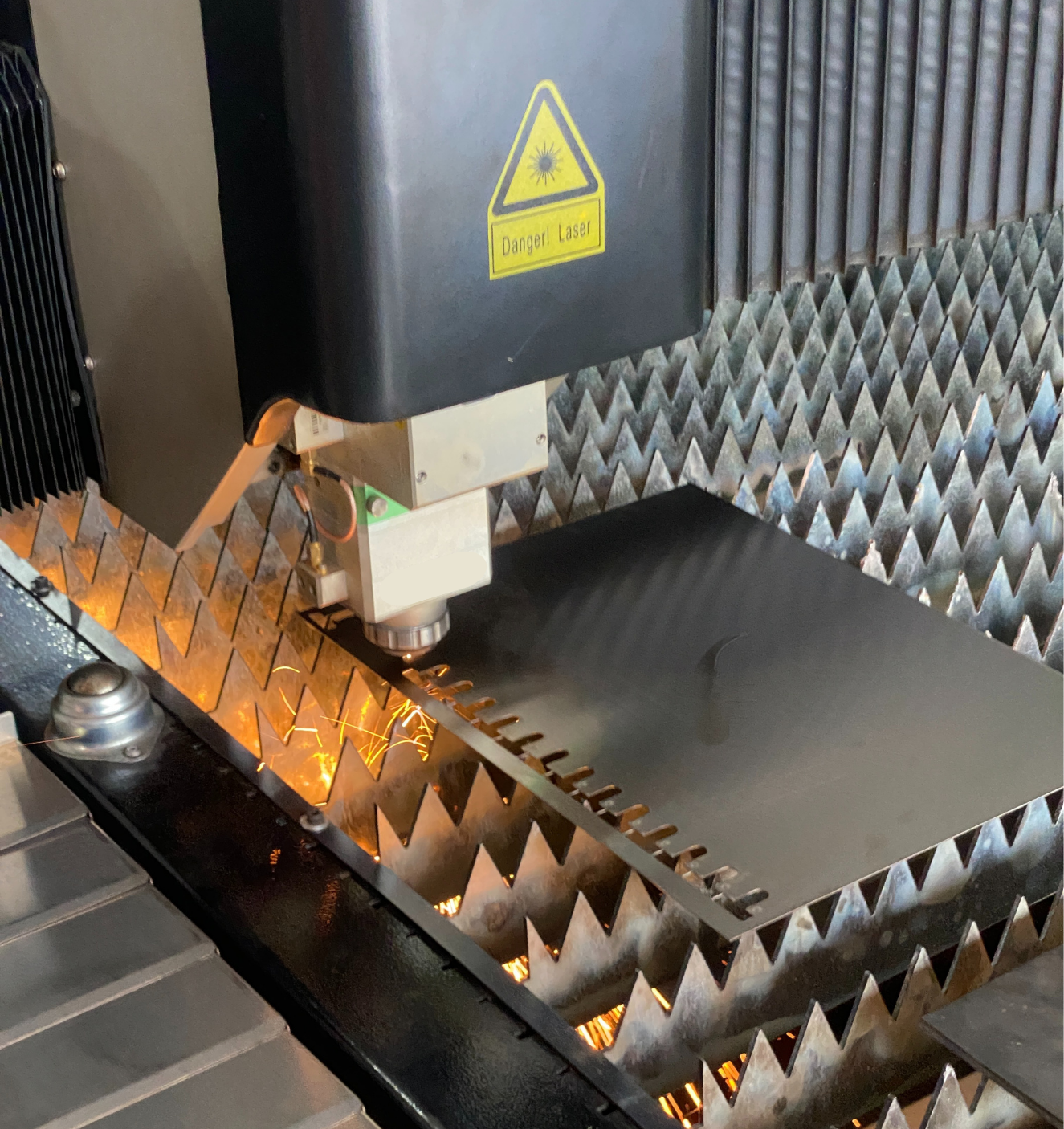

Beyond our core additive manufacturing processes, 3D LABS by TECHNOTRONIC FUTURISTICS offers a range of supporting services to help you take your product from concept to completion. From professional CAD design and precise 3D scanning to expert material selection, finishing, and scalable production, we provide end-to-end solutions that ensure your parts meet the highest standards of quality, performance, and reliability.

Our design team transforms your concepts into precise, manufacturable 3D models optimized for strength, efficiency, and cost. We assist through every stage from concept validation to ready-to-print product development.

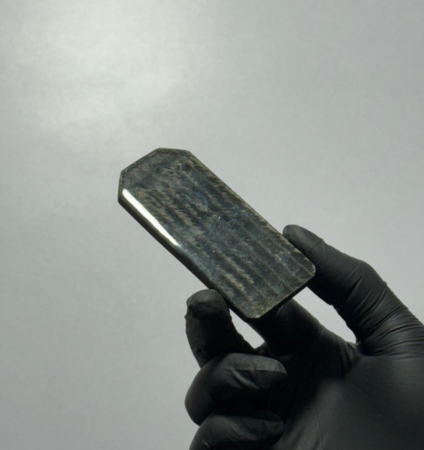

We use high accuracy 3D scanning to digitally capture physical parts for reverse engineering or quality inspection. This enables seamless reproduction, modification, or integration into your design workflow.

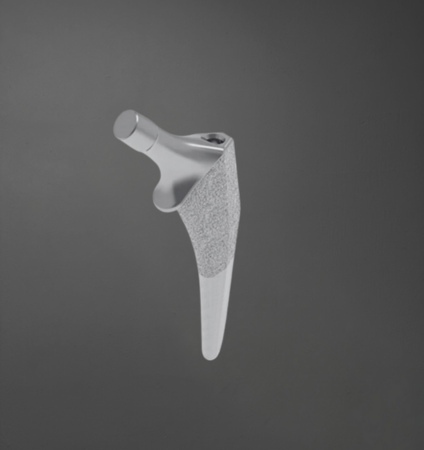

Choosing the right material is critical for performance, our experts guide you based on mechanical strength, temperature tolerance, and application demands. We help you achieve the perfect balance of durability, functionality, and finish.

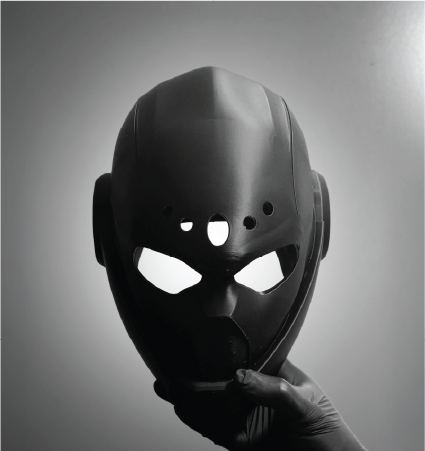

We offer advanced decaling and surface customisation options to give your 3D printed parts a professional, end-product finish. Our marking and printing solutions ensure both visual appeal and functional durability.

Our finishing services include sanding, painting, coating, and surface treatment to enhance aesthetics and performance. Every part is refined to meet your exact visual and functional requirements.

We offer scalable production solutions for prototypes, small batches, and custom parts. Get consistent quality and fast turnaround without the cost of traditional tooling.