Advanced Additive Manufacturing for Industrial & Engineering Applications

Process:

Capability:

Focus:

Outcome:

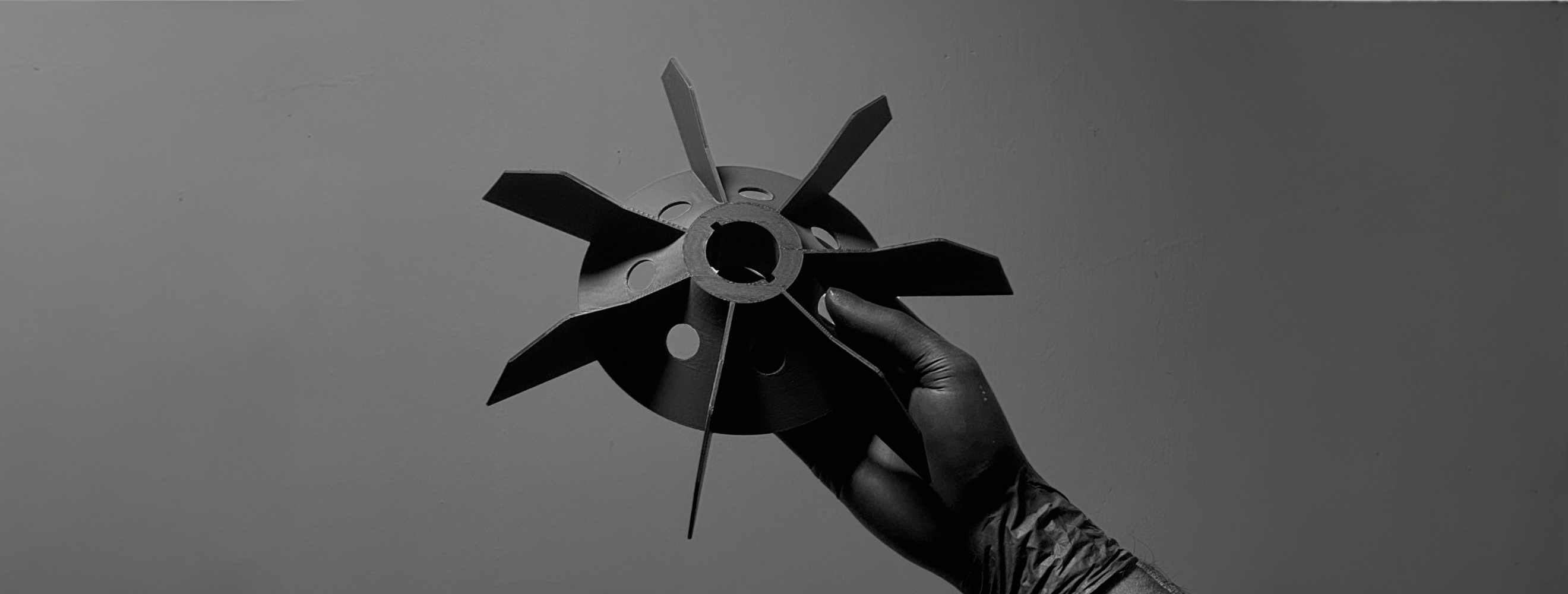

Additive manufacturing is transforming the industrial and engineering sectors by enabling the creation of high performance components with exceptional precision and design flexibility. It supports rapid prototyping, low-volume production, and complex geometries that are difficult to achieve with traditional manufacturing.

This technology minimizes lead times and material waste while improving design efficiency and overall product performance. By integrating advanced engineering principles with digital manufacturing, it accelerates innovation, enhances reliability, and drives industrial productivity forward.

Additive manufacturing empowers industries with precision, flexibility, and speed. Enabling efficient production of complex parts, prototypes, and tools for demanding engineering applications.

Through advanced additive manufacturing, we deliver robust industrial solutions that enhance performance, precision, and production efficiency. Our integrated FDM, SLA, SLS, and DMLS capabilities enable rapid prototyping, tooling, and end-use part production with consistent quality and reliability.

Additive Manufacturing in Industrial Sector