Multi material 3D printing is reshaping how functional products are designed and manufactured. By combining different materials within a single print, we can tailor strength, flexibility, durability, and performance exactly where they’re needed. This approach reduces the need for multi part assemblies, minimizes post-processing, and unlocks design possibilities that simply aren’t achievable with traditional manufacturing.

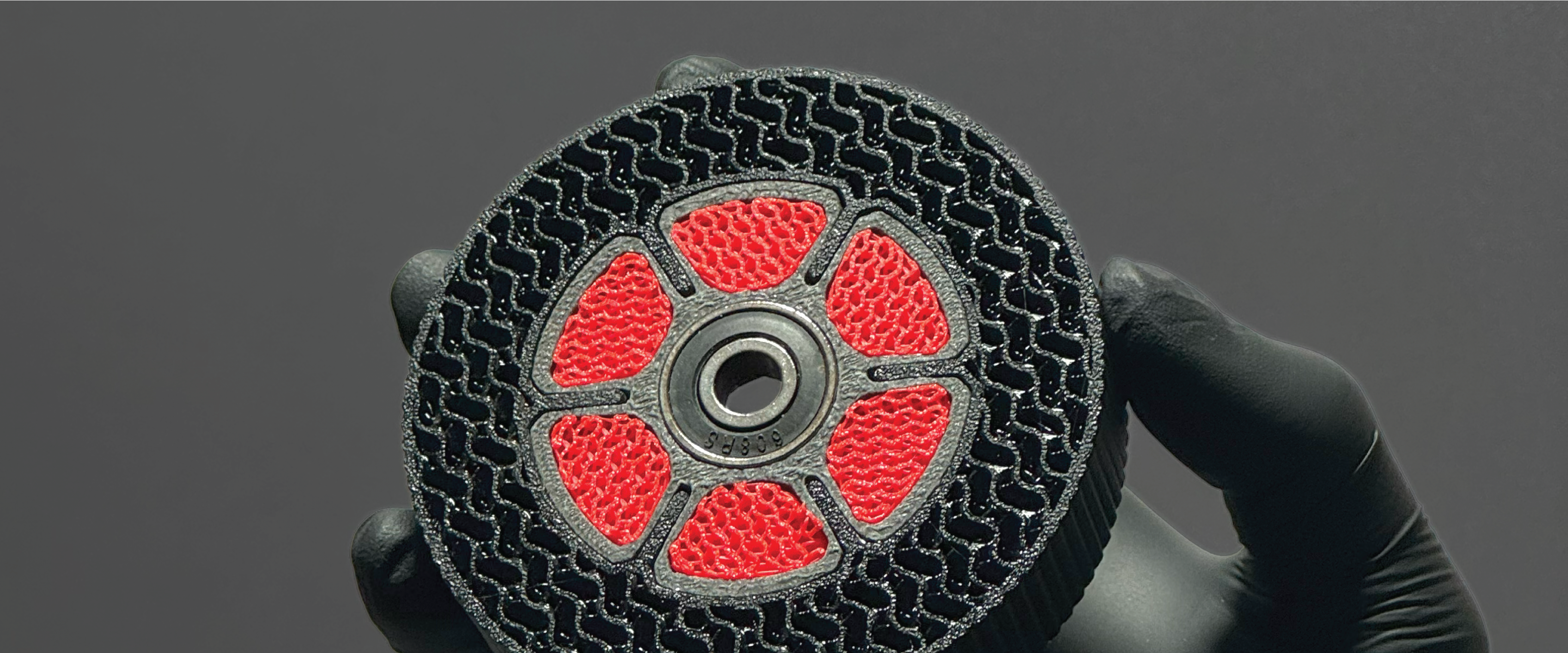

At 3D Labs by Technotronic Futuristics, we recently showcased this technology with a custom multi material castor wheel printed using TPU (black), ABS-CF (grey), and PLA (red). Each material serves a purpose, and together they outperform standard one material parts.

Multi material FDM/FFF 3D printing uses multiple nozzles or toolheads to deposit different materials in the same layer or in different regions of a part. This lets us create hybrid components that benefit from the strengths of each material:

The result is a part that is more than the sum of its materials.

In our castor wheel example, we utilized three distinct materials to achieve maximum efficiency:

🟦 ABS-CF (Grey)

Used for the wheel’s core structure.

This provides a robust load-bearing center.

🟥 PLA (Red)

Used for outer infill sections & accents.

Ideal for non-load bearing regions that still require shape and visual definition.

⬛ TPU (Black)

Used for the outer tire / shock-absorbing ring.

This makes the wheel smooth, quiet, and durable during use. Together, all three materials create a single functional part that would normally require assembly, screws, and multiple manufacturing processes.

1. Functional Optimization

Each section of the part is printed with the ideal material. No compromises only purposeful design.

2. Reduced Assembly Time

A multi part product becomes a single print, reducing labor and error.

3. Lower Manufacturing Costs

By combining inexpensive materials with high performance ones only where necessary, you get the best value for money.

4. Greater Durability

Bonded interfaces between materials often outperform glued or bolted parts.

5. Design Freedom

Engineers can create complex internal features, flexible joints, integrated mounts, and variable hardness zones.

6. Faster Prototyping

Test multiple material combinations in one print instead of manufacturing separate parts.

“If you’re engineering functional parts, looking to reduce manufacturing time, or simply want higher performance components, multi material 3D printing gives you a competitive edge.” 3D Labs

Whether you’re creating industrial components, prototyping a product, or developing a new idea, multi material 3D printing can dramatically improve your results.

At 3D Labs, we provide full support from material selection to design optimization and manufacturing ensuring your parts are strong, efficient, and cost effective.

Contact Technotronic Futuristics / 3D Labs today to get started on your next project.